If you’ve ever wondered how gold is efficiently extracted from mining operations, you’ll want to know the inner workings of how does a gold mining trommel work. This impressive machine is at the forefront of gold extraction, utilizing a unique mechanism to separate gold from other materials. By understanding the mechanics behind this process, you’ll gain insight into the efficient and precise methods used in the gold mining industry. So, let’s take a closer look at how a gold mining trommel works and uncover the secrets to successful gold extraction.

Overview of How Does a Gold Mining Trommel Work

Definition of a Gold Mining Trommel

A gold mining trommel is a piece of equipment used to separate gold-bearing ore from other materials in a gold mining operation. It consists of a cylindrical drum, usually made of steel, with small holes punched throughout the surface. The drum is tilted and set in motion, allowing the gold-bearing material to pass through the holes while any larger rocks and debris are retained inside.

Importance of Gold Mining Trommels

Gold mining trommels play a crucial role in the efficient extraction of gold from ore. They help maximize the efficiency of the gold recovery process by effectively separating gold particles from larger rocks and waste materials. This not only increases the overall gold recovery rate but also minimizes the environmental impact of mining operations by reducing the amount of waste material generated.

Historical Background

The use of trommels in gold mining can be traced back to ancient civilizations. Archaeological evidence suggests that ancient Egyptians, Romans, and Chinese civilizations used similar devices to extract gold from alluvial deposits. Over the years, advances in technology and engineering have led to the development of more efficient and robust gold mining trommels, greatly improving the productivity and effectiveness of gold mining operations.

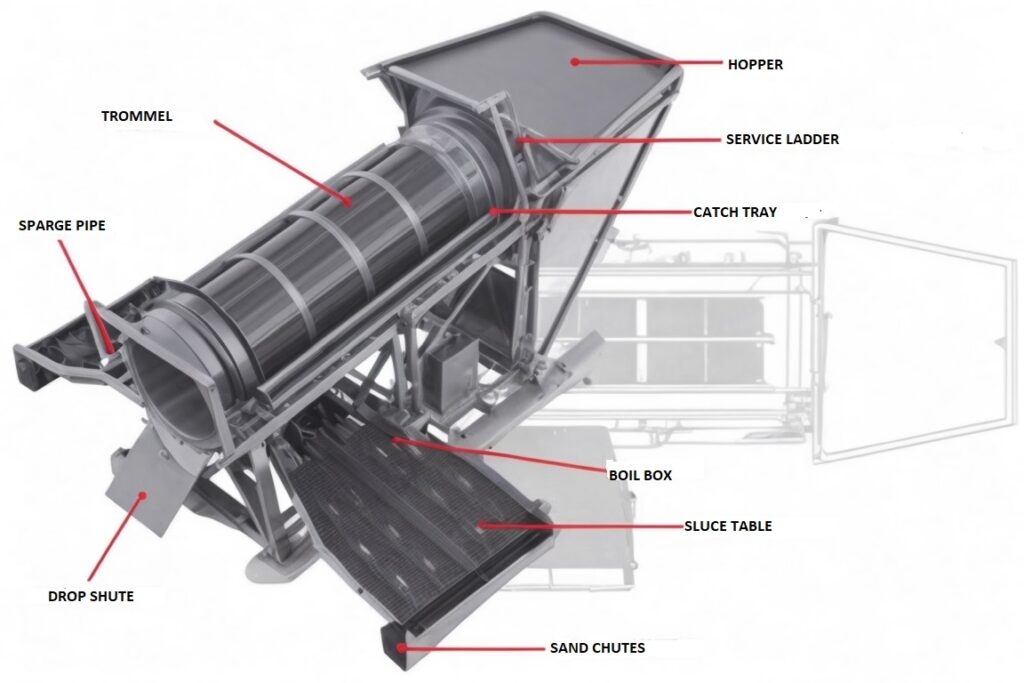

Design and Components of a Gold Mining Trommel

Basic Design

The basic design of a gold mining trommel typically consists of a cylindrical drum mounted on a frame. The drum is usually tilted at an angle to facilitate the movement of material through the trommel. It is important for the drum to be durable and strong, as it needs to withstand the impact of rocks and the constant rotation during operation.

Structure and Frame

The frame of a gold mining trommel provides stability and support for the drum and other components. It is typically made of sturdy materials such as steel or aluminum to ensure durability and longevity. The frame is designed to withstand the vibrations and stress generated during the operation of the trommel.

Screening System

The main purpose of a gold mining trommel is to separate gold-bearing material from larger rocks and debris. This is achieved through the use of a screening system. The drum of the trommel contains small holes, often referred to as screening media, which allow the smaller particles of gold-bearing material to pass through while retaining the larger rocks and waste material.

Conveyor System

In order to efficiently process large volumes of material, a gold mining trommel is often equipped with a conveyor system. This system transports the material from the hopper to the drum, ensuring a continuous flow of material through the trommel. The conveyor system can be adjustable in height and speed to accommodate different mining conditions.

Principles of Operation

Input and Feed System

The input and feed system of a gold mining trommel is responsible for introducing the material into the trommel for processing. It consists of a hopper, a feeder, and a water supply. The hopper is generally filled with the gold-bearing material, which is then fed into the trommel using a feeder. Water is also supplied to the trommel to aid in the separation process and to wash away any excess debris.

Material Screening

Once the material enters the trommel, it undergoes a screening process. The gold-bearing material is separated from larger rocks and waste material by the screening media, which allows smaller particles to pass through while retaining the larger ones. The size classification of the material is an important aspect of the screening process, as it determines the efficiency of gold extraction.

Gold Extraction and Recovery

The gold extraction and recovery process in a gold mining trommel involve several mechanisms. As the trommel rotates, the heavier gold particles are captured and retained in the trommel barrel due to centrifugal force. The retained gold particles are then directed to a sluice box, where they are further concentrated and trapped by riffles. By utilizing centrifugal force, gravity, and water flow, the gold extraction process is optimized for maximum efficiency.

Discharge and Waste Handling

After the gold-bearing material has been processed and the gold particles have been extracted, the remaining waste material, commonly referred to as tailings, needs to be discharged and handled appropriately. This is typically done through an outlet and discharge chute, which directs the waste material away from the trommel. Proper tailings management is crucial for environmental considerations and to ensure the efficient operation of the trommel.

Input and Feed System

Hopper

The hopper of a gold mining trommel is where the gold-bearing material is initially placed for processing. It is designed to hold a sufficient amount of material to ensure a continuous feed into the trommel. The size and capacity of the hopper can vary depending on the scale of the mining operation and the desired processing rate.

Feeder

The feeder is responsible for introducing the material from the hopper into the trommel at a controlled feed rate. It ensures a consistent flow of material into the trommel, preventing any blockages or uneven distribution. Feeders can be designed with adjustable settings to accommodate different types of material and optimize the efficiency of the trommel.

Water Supply

Water plays a crucial role in the operation of a gold mining trommel. It is used to facilitate the separation of gold particles from other materials, as well as to wash away any excess debris. A reliable and sufficient water supply is essential for the efficient operation of the trommel. The water supply can be sourced from various methods, such as water pumps or natural water sources.

Material Screening

Size Classification

Size classification is an important aspect of material screening in a gold mining trommel. It involves separating the material into different sizes, with the smaller particles passing through the screening media and the larger ones being retained. This classification allows for more efficient gold extraction and prevents oversized rocks from damaging the trommel or impeding the flow of material.

Trommel Barrel

The trommel barrel, also known as the drum, is a key component of the material screening process. It is where the gold-bearing material is introduced and undergoes the separation process. The trommel barrel is usually made of steel and is designed with small holes punched throughout the surface to allow the smaller particles to pass through.

Screening Media

The screening media, often referred to as the trommel screen, is the surface of the trommel barrel that contains the small holes for material separation. It is typically made of metal or polyurethane and is available in various configurations, such as woven wire mesh or perforated plate. The choice of screening media depends on factors such as the size of the gold particles and the desired processing rate.

Vibration and Rotation

The trommel barrel is set in motion through the use of a motor or engine, which causes the drum to rotate. The rotation helps to break up the material and facilitate the separation process. Some trommels also incorporate vibration mechanisms, which further aid in the screening process by shaking the material and allowing for improved separation efficiency.

Gold Extraction and Recovery

Capture of Heavy Minerals

During the operation of a gold mining trommel, the heavier gold particles are captured and retained within the trommel barrel due to centrifugal force. This mechanism ensures that the gold is concentrated and prevented from being washed away with the waste material. The capture of heavy minerals is essential for maximizing the overall gold recovery rate.

Sluice Box

After the gold particles are captured in the trommel barrel, they are directed to a sluice box for further concentration and trapping. The sluice box is designed with riffles, which create zones of varying water flow and capture the gold particles as the material moves along the sluice. The design of the sluice box is crucial for efficient gold extraction and recovery.

Riffles

Riffles are raised bars or ridges within the sluice box that create turbulence in the water flow. They serve to capture and trap the gold particles as the material passes over them. The spacing and design of the riffles play an important role in optimizing the gold extraction process, ensuring maximum recovery of the precious metal.

Centrifugal Force

Centrifugal force is a key principle utilized in gold extraction within a trommel. The rotation of the trommel barrel generates centrifugal force, which causes the heavier gold particles to move towards the outer edge of the barrel and be retained. By harnessing this force, the efficiency of gold extraction is significantly enhanced.

Gold Traps

Gold traps are devices or features within the trommel or sluice box that further enhance the capture and retention of gold particles. They can be strategically positioned to take advantage of the flow of material and water, maximizing the chances of capturing any remaining gold. Gold traps are designed to prevent gold particles from escaping the extraction process.

Discharge and Waste Handling

Outlet and Discharge Chute

Once the gold particles have been extracted and concentrated, the waste material, or tailings, needs to be discharged from the trommel. This is typically done through an outlet and discharge chute, which directs the tailings away from the trommel and into designated waste areas. The outlet and discharge chute are designed to ensure a smooth flow of material and minimize any blockages.

Tailings Management

Proper management of tailings is essential for the efficient operation of a gold mining trommel. Tailings can contain residual gold particles and other potentially harmful substances. They need to be handled and disposed of in an environmentally responsible manner to minimize the impact on surrounding ecosystems. Tailings management techniques include dewatering, containment, and reclamation.

Environmental Considerations

Gold mining trommels, like any mining operation, have environmental considerations that need to be addressed. These include mitigating the impact of mining activities on soil, water quality, and wildlife habitats. Proper planning and implementation of environmental management practices are necessary to ensure sustainable and responsible gold mining operations.

Efficiency and Optimization

Enhancements for Higher Efficiency

The efficiency of a gold mining trommel can be enhanced through various enhancements. These may include the use of advanced screening media, optimized drum design, and improved water flow systems. By continuously seeking ways to improve efficiency, gold mining operations can maximize their gold recovery rates and minimize waste.

Optimizing Trommel Speed

The speed at which the trommel barrel rotates can impact the efficiency of gold extraction. Optimizing the trommel speed involves finding the right balance between material throughput and gold capture. Adjusting the speed based on the characteristics of the material being processed can help achieve optimal results.

Optimizing Water Flow

Water flow plays a critical role in the separation and extraction of gold in a trommel. Optimizing the water flow involves finding the right balance between providing enough water to facilitate the separation process while avoiding excessive water that can hinder the efficiency of gold recovery. Proper water flow management is essential for maximizing overall trommel performance.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are crucial for ensuring the effective operation of a gold mining trommel. This includes inspecting and cleaning the screening media, checking for any wear or damage, and ensuring that the mechanical and electrical components are functioning properly. In the event of any issues or breakdowns, prompt troubleshooting and repairs are necessary to minimize downtime and maintain operational efficiency.

Advantages and Limitations of Gold Mining Trommels

Advantages

Gold mining trommels offer several advantages over other gold extraction methods. They are highly efficient in separating gold particles from waste material, resulting in higher gold recovery rates. Trommels also allow for continuous operation, reducing downtime and increasing overall productivity. Additionally, trommels are versatile and can be used in various mining applications, from small-scale operations to large-scale mining projects.

Limitations and Challenges

Despite their numerous advantages, gold mining trommels do have some limitations and challenges. One of the main challenges is the control of water flow and the need for a reliable water supply. The effectiveness of gold extraction can be affected by improper water flow management. Additionally, the trommel screen can become clogged or damaged by large rocks and debris, requiring regular maintenance and cleaning.

Applications and Industry Examples

Small-Scale Mining

Gold mining trommels are commonly used in small-scale mining operations. They offer a cost-effective and efficient method of extracting gold from relatively small amounts of gold-bearing material. Small-scale miners can utilize trommels to process their ore on-site, minimizing the need for costly transportation to off-site processing facilities.

Large-Scale Mining

Gold mining trommels are also utilized in large-scale mining operations. These operations often involve processing large volumes of material, and trommels provide an efficient solution for separating gold from waste. Trommels can be customized to meet the specific requirements of large-scale mining projects, allowing for high-capacity processing and increased gold recovery rates.

Sampling and Exploration

Trommels are commonly used for sampling and exploration purposes in the mining industry. They allow geologists and mining professionals to quickly and efficiently assess the gold-bearing potential of a particular area. By processing smaller amounts of material, trommels enable the collection of representative samples for further analysis and decision-making in terms of future mining operations.

Environmental Remediation

Gold mining trommels can also be utilized in environmental remediation projects. They can be used to separate and process contaminated material, such as mine tailings, in order to extract any remaining valuable metals or minerals while reducing the environmental impact. Trommels offer a sustainable approach to remediation by maximizing resource recovery and minimizing waste.

In conclusion, gold mining trommels play a vital role in the efficient extraction of gold from ore. Their design and components, such as the screening system and conveyor system, enable effective separation and extraction of gold particles. The input and feed system, material screening, gold extraction and recovery, and proper discharge and waste handling are key principles of operation. The trommel’s efficiency and optimization can be enhanced through various measures, including optimizing speed and water flow, as well as regular maintenance. While trommels offer many advantages, such as high gold recovery rates and versatility, they also have limitations and face challenges. Their application ranges from small-scale mining to large-scale mining, sampling and exploration, and environmental remediation. Gold mining trommels continue to play a crucial role in the gold mining industry, ensuring efficient and sustainable gold extraction.

Want build your own trommel? Read our DIY article below:

Build Your Riches: 3 Essential DIY Gold Prospecting Equipment Projects